Automated packaging lines

Optimise your packaging processes with an automated solution

Discover the future of packaging now and take your company to the next level! We offer you innovative solutions and comprehensive expertise for your entire packaging process.

Your ideal solution for individual requirements

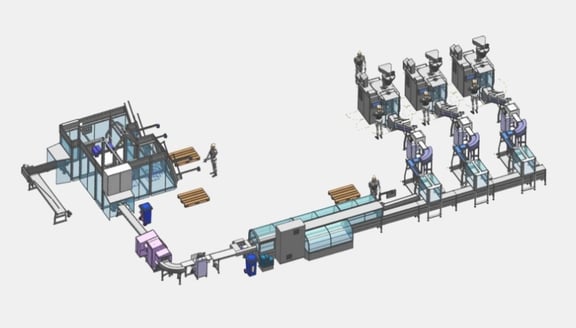

ROVEMA offers you suitably coordinated solutions for every step of the packaging process:

- Our high-quality dosing systems (1) guarantee precise filling quantities.

- Our vertical flow-wrapping machines (2) ensure efficient, flexible packaging.

- We also integrate cartoners (3) and end-of-line packaging machines (4) from our own production for optimum line synchronisation.

- It is also possible to integrate additional machines into packaging lines, e.g. palletisers, X-Ray, check weigher, etc.

Increase the efficiency of your processes with ROVEMA!

Planning, integration, testing and commissioning of the complete packaging line in our company

Take advantage of perfectly synchronised and automated packaging lines from a single source to optimise your production processes and ensure long-term success. Rely on our specialists to help you plan and implement complex packaging lines efficiently in order to minimise investment risks and ensure the greatest possible benefit for your company.

On request, we can integrate the customer's own systems and external components. Before delivery, the packaging line is fully assembled and tested as part of a Factory Acceptance Test (FAT) to ensure reliable acceptance. Modern control systems enable seamless system synchronisation.

The advantages of packaging lines made by ROVEMA

- One contact for everything

- Worldwide service availability guaranteed

- Acceptance with original product and packaging material

- High availability of spare parts

- Reliable commissioning planning

- MES connection during commissioning

- Hardware and control system

- 3D representation of the entire line

- Flexible integration of external components

Q&A: Your questions, our answers

Our ROVEMA experts support you in the planning of complex, automated packaging lines - including the selection and integration of machines, coding and inspection systems, interface coordination and logistical process optimization to ensure maximum efficiency and investment security.

ROVEMA offers practical training programs that can be flexibly adapted to your requirements. The aim is to optimally prepare your personnel for the operation and maintenance of the machine. The training content combines theory and practice, enabling safe and efficient handling of the machine right from commissioning.

The types of training offered include

- Classroom training

- Live web training

- Learning platform & blended learning

- Training videos and documents

Our service contracts (BASIC, COMFORT, COMFORT+, PREMIUM) provide you with packages that are individually tailored to your requirements. This ensures long-term machine availability, reduces downtimes and benefits from predictable maintenance costs and fast support from qualified technicians.

We support you with our comprehensive range of services to ensure the long-term performance and availability of your machine. With over 15,000 original parts in stock, we ensure the worldwide supply of spare parts. In addition, targeted modernizations enable existing machines to be adapted to new requirements, for example the use of sustainable packaging materials. In addition, tailor-made retrofit kits are available for the targeted expansion and technical optimization of existing packaging machines or systems.

For an economical and resource-saving alternative to a new machine, we offer a general overhaul of used machines with ROVEMA Second Life - including new control systems, servo motors, format parts and more.

ROVEMA Case Studies: From practice for practice

We deliver experience, responsibility and continuity

Our team analyzes your individual requirements and develops suitable solutions for your project.

Testing options for packaging materials:

- Machinability of the packaging material

- Expected output

- Coefficient of friction

- Tensile test (seal strength)

- Microtome cuts

- Density tests

Benefit from our industry-specific know-how

from over 30,000 international projects in 14 sectors.